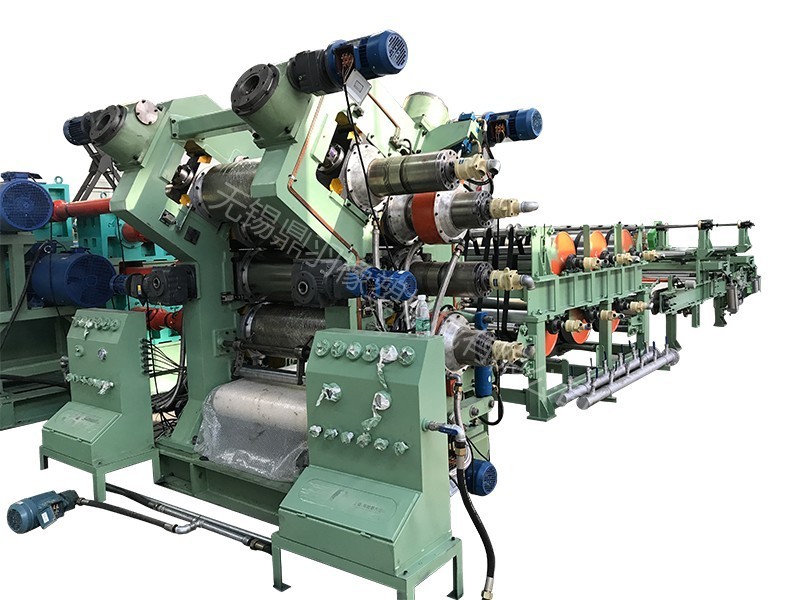

Main uses of the kneader

Release time:

2024-12-13

A kneader is a machine that uses a pair of rotors with specific shapes that rotate relative to each other. It intermittently plasticizes and mixes polymer materials in a closed state under adjustable temperature and pressure.

- Used for the mastication and mixing of natural rubber and other polymeric elastomers.

A mill is a machine that uses a pair of rotors with specific shapes that rotate relative to each other. Under adjustable temperature and pressure in a closed state, it intermittently masticates and mixes polymeric materials. In the processing of natural rubber and other polymeric elastomers, the mill, through strong stirring and shearing, ensures that the rubber compound and compounding agents are fully mixed, improving the plasticity of the rubber compound. For example, the main purpose of masticating rubber in a mill is to break the macromolecular chains under mechanical, thermal, and chemical actions, increasing plasticity to meet various process requirements in manufacturing, such as compounding agent mixing, calendering, pattern shape, molding, rubber flow, and adhesion.

- Widely used in the processing of rubber, plastic, and other materials, such as mixing, mastication, and extrusion.

A closed-type rubber mill, or mill for short, is mainly used for the mastication and mixing of rubber, and is also used for mixing plastics, asphalt materials, felt materials, enamel materials, and various synthetic resin materials. The main functions of a mill include mixing, mastication, and extrusion processing. During mixing, the mill uses its internal stirrer and heating system to bond different types of rubber or plastic materials together, ensuring uniform material mixing. During mastication, the mill uses high-speed stirring and high-temperature heating to melt the raw materials and form a uniform mixture. During extrusion processing, the mill extrudes the plasticized material through the extrusion port to form the desired product. The application and role of mills in the rubber industry are specifically reflected in plasticization, mixing, calendering, cooling, and granulation, providing strong support for the preparation of high-performance rubber products. At the same time, mills also play an important role in the processing of plastics and other materials. Through stirring, heating, and mechanical transmission, they ensure uniform material mixing and complete plasticization, ultimately achieving product extrusion processing.